Equipment R&D and Manufacturing

Continue to develop equipment, continue to innovate independently and create excellent results

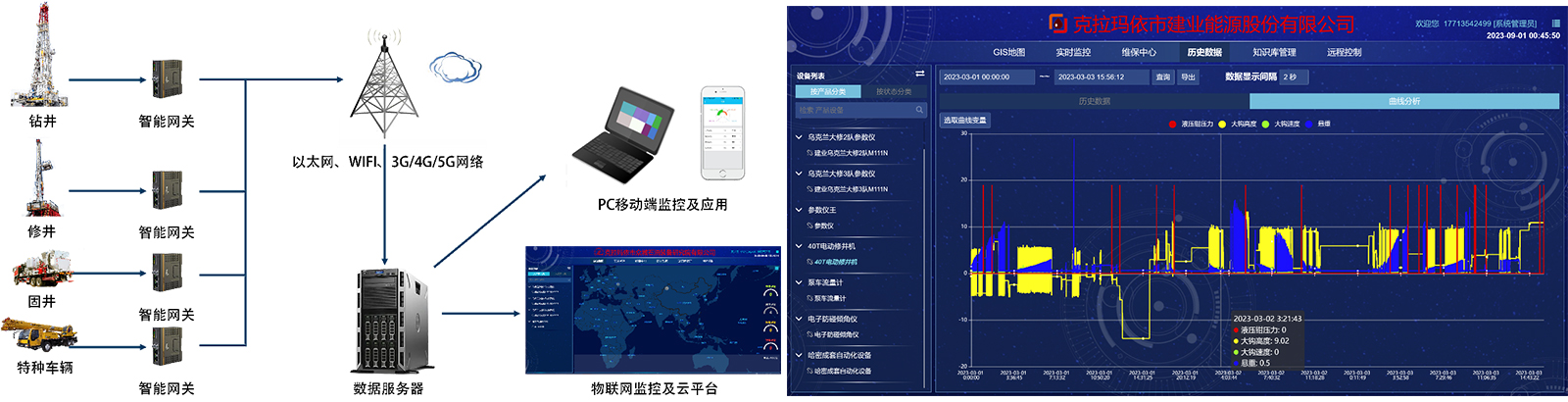

Drilling and repair equipment IoT and cloud platform

The IoT and cloud platform of drilling and repair equipment uses IoT technology and interconnected cloud platform to collect and analyze data in real time during drilling and repairing wells to realize intelligent management and operation and maintenance of drilling and repairing equipment, helping oil service companies to achieve efficient and refined management of on-site equipment, realize energy saving, consumption reduction, cost-reduction and efficiency improvement, and help companies improve their core competitiveness.

Device List

1) Drilling and repairing parameters monitoring system:

The ZCP-R-02 integrated drilling and repair parameter monitoring system is a parameter instrument system designed and produced by our company for drilling rigs and repair machines. It can realize the collection, display, control and transmission of signals required during drilling and repairing. It adopts wireless technology design and is convenient to install, making it more suitable for harsh environmental conditions at drilling and repairing operations. It can help drill drivers, central control room, project department, and data center to grasp the working status of drilling and repair machines in real time, networked data information transmission, WEB release methods, and end users browse and monitor in real time.

| Main monitoring parameters and technical indicators (can be optional on demand) | |||||

| Suspension and drilling pressure | Riser pressure | Torque of the hoist | |||

| Measurement range: | 0-500×10kN | Measurement range: | 0 ~40MPa | Measurement range: | 0 ~100kN |

| Measurement error: | ≤±1.5% | Measurement error: | ≤±1.5% | Measurement error: | ≤±2.5% |

| Turntable torque | Mud reflux | Mud tank level | |||

| Measurement range: | 0 – 40kN.m | Measurement range: | 0-100% | Measurement range: | 0 – 3m |

| Measurement error: | ≤±5% | Measurement error: | ≤±2% | Measurement error: | ≤±2.5% |

| Turntable speed | Slurry pump pump | Train location | |||

| Measurement range: | 0 – 300 r/min | Measurement range: | 0 – 300 rush/min | Measurement range: | 0~30m |

| Measurement error: | ≤±2.5% | Measurement error: | ≤±2.5% | Measurement error: | ≤±2.5% |

| Combustible gases | Hydrogen sulfide | Other related derivative parameters | |||

| Measurement range: | 0~100%LEL | Measurement range: | 0~100ppm | Jing Shen | Drill bit position |

| Measurement error: | ≤±5% LEL(F·S) | Measurement error: | ≤±5% F·S | Drilling pressure | Well site temperature |

2) Drilling and repairing equipment IoT cloud platform

The IoT cloud platform of drilling and repair equipment realizes real-time monitoring, operating status recording, fault alarm, notification and remote control of all modules on the drilling and repair equipment site. Users can easily view the operating status of the device through mobile phones, WeChat mini programs, and WEB clients, know the occurrence of faults in real time, and monitor on-site equipment on demand and other functions. It greatly reduces the working intensity of management and maintenance personnel, and can also deal with faults and maintenance equipment in a timely manner, improve production efficiency, and reduce operation and maintenance costs. At the same time, it provides fixed reports, visual charts, large-screen cockpits and other display forms to provide decision-making support and management collaboration for enterprises.

Other businesses